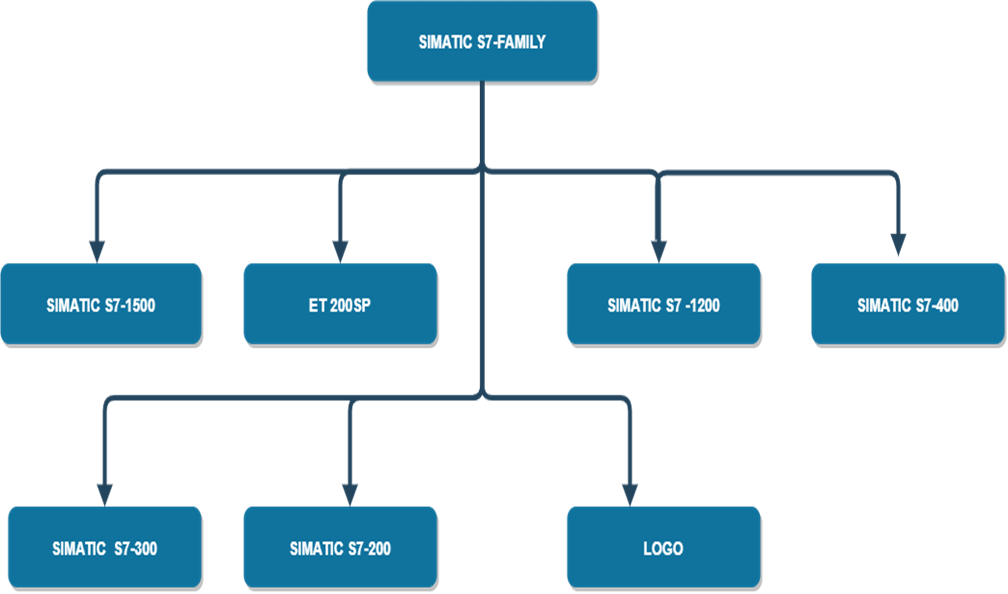

Siemens PLC System Overview

Various Types of PLCs

LOGO

SIMATIC S7-200

SIMATIC S7-300

SIMATIC S7-400

SIMATIC S7-1200

SIMATIC ET-200SP

SIMATIC S7-1500

LOGO

Overview:Siemens LOGO, introduced in 1996, is a small logic controller that revolutionized the market with its speed, simplicity, and space-saving design. It is ideal for small automation projects.

Features:

Expandable modules, supporting up to 24 digital inputs, 20 digital outputs, 8 analog inputs, and 8 analog outputs.

Software:

Programming is done using LOGO SOFT.

Communication:

Older versions use a Siemens logo USB cable, while newer versions utilize an Ethernet cable (RJ-45) for communication.

SIMATIC S7-200

Overview:The S7-200 is a compact PLC designed for small industrial applications. It combines Siemens' SIMATIC automation products with SINAMICS drive products, creating an economical and user-friendly micro-automation solution.

Features:

Compact PLC suitable for small industrial applications.

Supports up to 38 analog inputs/outputs and 256 digital inputs/outputs.

Can be expanded with up to 7 expansion modules.

Software:

Programmed using STEP 7 Micro/WIN.

Communication:

Uses RS-232/PPI multi-master cable via RS485 connector with a baud rate of 187kbits.

PC/PLC communication via MPI using a PC adapter.

SIMATIC S7-300

Overview:The S7-300 is a modular, universal controller designed to save installation space. Its modules can be used for system central expansion or distributed structures based on task requirements, making it cost-effective to store spare parts.

Features:

Rack-type PLC, expandable up to 8 input/output modules per rack.

Data transfer to other modules via interface modules.

Up to 4 racks can be expanded within an S7-300 PLC panel cabinet.

Based on a serial communication system, suitable for both small and process industries.

CPU Models:

Standard CPUs: CPU 312, CPU 314, CPU 315-2DP, CPU 315-2PN/DP, CPU 317-2PN/DP.

Fail-Safe CPUs: CPU 315F-2DP, CPU 315F-2PN/DP, CPU 317F-2PN/DP.

Fail-Safe CPUs:

Always read device or process variables, detecting unsafe or risky conditions to immediately react and shut down the equipment or process, entering a safe state.

Software:

Programmed using STEP 7 V5.

HMI and SCADA are managed using WinCC flexible.

TIA Portal STEP 7 Professional is also used.

Communication:

RS485/PROFIBUS PC adapter via MPI, Ethernet cable for PROFINET.

SIMATIC S7-400

Overview:The S7-400 is designed for system solutions in manufacturing and process automation, handling data-intensive tasks typical of process industries.

Features:

High-performance CPUs for demanding performance ranges.

Capable of operating up to 21 expansion units.

Modular design.

Each CPU has 8 slots, each with its own input/output.

Up to 6 interface modules can be inserted.

Standard S7-400 systems support redundant power supplies for up to 18 modules.

CPU Models:

Standard CPUs: 412, 414, 416, 417.

Fail-Safe CPUs: 414f, 416f.

CPU 416-3 PN/DP with integrated PROFINET functionality.

Software:

Programmed using STEP 7 V5.

HMI and SCADA are managed using WinCC flexible.

TIA Portal STEP 7 Professional is also used.

Communication:

RS485/PROFIBUS PC adapter via MPI, Ethernet cable for PROFINET.

SIMATIC S7-1200

Overview:The S7-1200 is a basic controller designed for lower performance ranges requiring flexibility and efficiency. It is compact and versatile, allowing for additional I/O modules to expand its capabilities.

Features:

Compact design, versatile functionality.

I/O integrated, expandable with additional signal boards.

S7-1200 CPUs with safety integration handle standard and safety tasks.

All CPUs can be expanded with one additional signal board, adding up to three communication modules.

Integrated with 6 DI/4DQ, expandable via signal boards.

Modules support 8, 16, or 32 input/output channels.

Integrated PROFINET interface for programming CPU and communicating with other controllers and drives, supporting serial communication, PROFIBUS, and IO Link.

Working and Load Memory:

Working memory functions similarly to a PC's RAM.

Load memory functions similarly to a PC's hard drive.

Software:

TIA Portal v13, v14, v15.

PROFINET Industrial Ethernet (RJ-45), PROFIBUS DP, MODBUS, etc.

SIMATIC ET 200SP

Overview:ET 200SP is one of the most popular remote I/O units on the Siemens market. It features a set of input/output modules near factory sensors and actuators at one end—connected to a control room PLC at the other end via a single cable for PROFINET communication.

Features:

A distributed controller based on SIMATIC ET200SP.

Compact I/O system for control cabinets with high flexibility and performance, including Fail-Safe peripheral modules.

Interface modules connect the ET200SP station to the automation landscape's bus system. Choose from 5 types of PROFINET interface modules, high-speed function modules, or advanced function modules.

What is SIMATIC S7 -1500?

The SIMATIC S7-1500 is an advanced programmable logic controller (PLC) within the SIMATIC S7 family, designed for rapid response and optimal system performance. It offers both standard and failsafe CPU versions to cater to diverse industrial needs. By utilizing the SIMATIC S7-1500, users can achieve top-notch performance while ensuring future-proof integration into evolving technologies, facilitating even the most intricate machine designs during digital transformations.

This PLC executes user programs and seamlessly integrates with other automation components via networking capabilities. The failsafe CPU variants are specifically tailored for safety-critical applications in machinery and plants. Catering to small to medium-sized requirements, the S7-1500 combines compact design with integrated inputs and outputs, enhancing usability and efficiency.

A notable feature of the S7-1500 is its built-in display and keypad, which enables on-site configuration, diagnostics, and direct IP address management without external tools. For security enhancements, password changes can also be made through this interface. Moreover, the system supports expansion up to 32 modules, adaptable to various application sizes and complexities.

Standard CPU options like the CPU1511-1PN cater to smaller applications, while models such as the CPU1518-4PN/DP are suited for medium-sized tasks. The choice depends on specific application demands, communication protocols, and processing speeds required by the industry or facility.

The S7-1500 is well-suited for high-speed environments typical of assembly lines and ensures redundancy through PROFINET synchronization of CPUs.

Software & Communication:

Compatible Software: TIA Portal V13, V14, and V15. Projects can be migrated from older software like STEP 7 to these newer platforms.

Communication Protocols: Supports Industrial Ethernet (RJ-45), PROFINET, and PROFIBUS.

Advantages & Disadvantages of PLC Systems:

Pros:

Versatility & Space Efficiency: Saves space within control panels and reduces cabinet size.

Cost Reduction: Lowers spare parts inventory and associated costs.

Reliability & Flexibility: Enhances system reliability, flexibility, and accuracy.

Ease of Integration: Facilitates easy communication with computers and various industrial protocols like PROFIBUS, PROFINET, MODBUS, and TCP/IP.

Low Maintenance: Requires minimal maintenance, reducing operational expenses.

Automation Benefits: Decreases need for manual supervision, thereby cutting labor costs.

Hazardous Area Applications: Safe for use in potentially dangerous environments.

Modularity: Easily expandable by adding modules for additional functions like motor control or signal processing.

Remote Operation: Supports remote monitoring and control capabilities.

Error Detection: Simplifies troubleshooting and error resolution.

Cons:

Migration Limitations: Older PLC programs (e.g., S7-200) may not be easily transferrable to newer software platforms like TIA Portal.

Speed Constraints: Some compact PLCs might not be suitable for very high-speed applications.

Major Applications of PLCs in Industry:

Steel manufacturing

Glass production

Paper mills

Textile industries

Cement works

Food processing

Oil and gas facilities

Wind energy systems

Robotic automation

Chemical plants

Refrigeration processes

Pharmaceutical manufacturing

PLCs serve as the backbone of automation across these sectors, driving efficiency, precision, and innovation in modern industrial operations.